Tanebasami

Made in

Japan

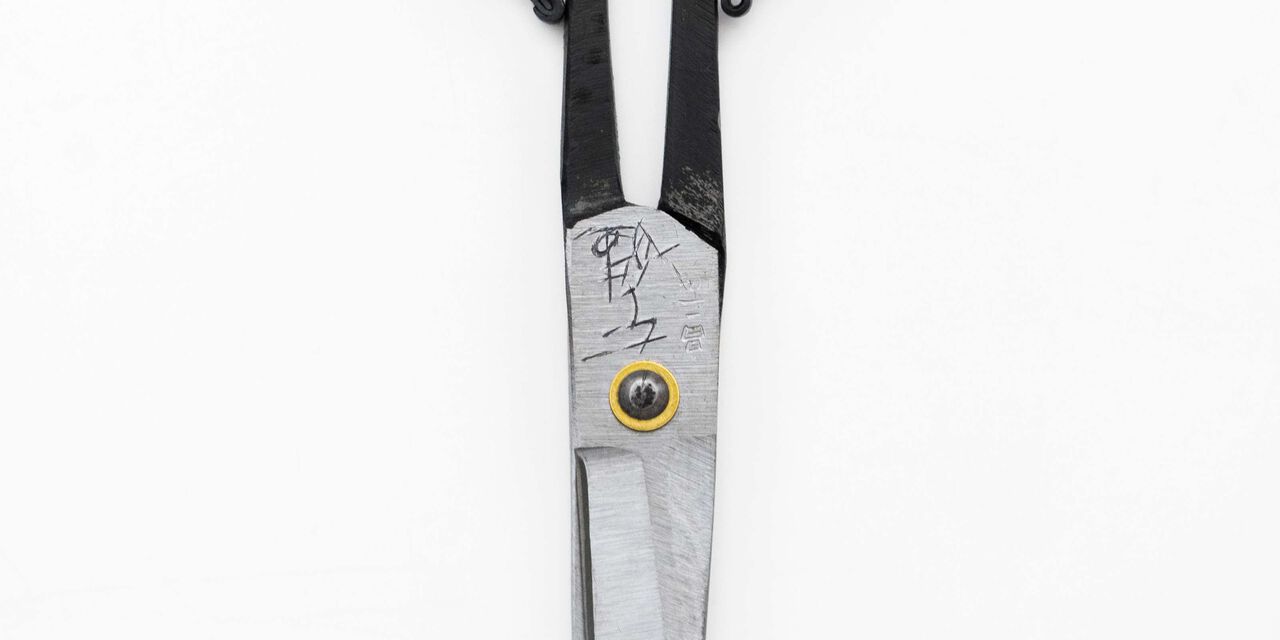

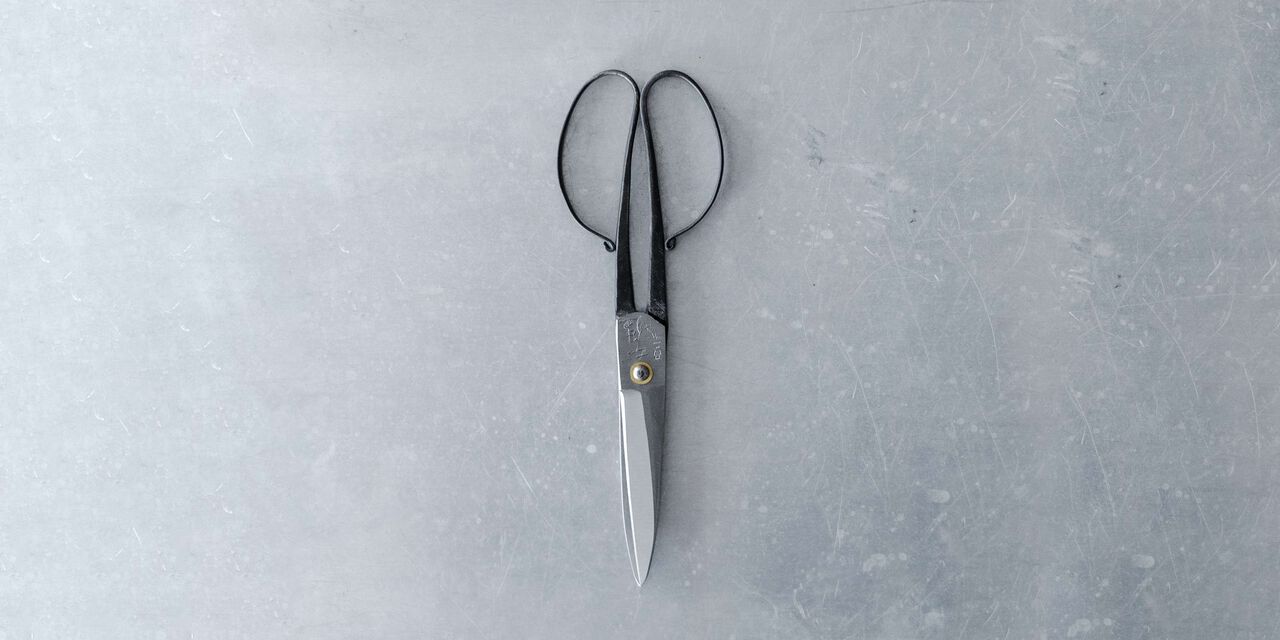

Beautiful handmade shears made by a traditional method in Kagoshima.

Tanegashima Island, located in the south of Kagoshima Prefecture, is rich in iron sand carried by the Kuroshio Current. It is said that Chinese blacksmiths introduced guns and shears in 1543. The traditional forging skills of Tanegashima have been passed down from guns and swords to shears and kitchen knives.

At its peak, there were nearly 30 manufacturing houses that distributed their products throughout Japan, but today there are only three. One of them, Umeki Hon-tanebasami Seisakujyo, is trying to preserve the technique and sharpness of Tanebasami shears for future generations.

The blade of Tanebasami shears is warped, or "neri," so that the blades rub against each other and are sharpened simultaneously with each cut. That's why you can enjoy these shears as everyday tools that will last you a long time.

Tanebasami shears, designated as a national intangible folk cultural property, have two blades that rub together to cut, which is considered a good omen and means "two people working together to open up their lives".

Tanegashima Island, located in the south of Kagoshima Prefecture, is rich in iron sand carried by the Kuroshio Current. It is said that Chinese blacksmiths introduced guns and shears in 1543. The traditional forging skills of Tanegashima have been passed down from guns and swords to shears and kitchen knives.

At its peak, there were nearly 30 manufacturing houses that distributed their products throughout Japan, but today there are only three. One of them, Umeki Hon-tanebasami Seisakujyo, is trying to preserve the technique and sharpness of Tanebasami shears for future generations.

The blade of Tanebasami shears is warped, or "neri," so that the blades rub against each other and are sharpened simultaneously with each cut. That's why you can enjoy these shears as everyday tools that will last you a long time.

Tanebasami shears, designated as a national intangible folk cultural property, have two blades that rub together to cut, which is considered a good omen and means "two people working together to open up their lives".

Dimensions: Length 180mm Width 60mm (Blade length 65mm)

Material: Iron, Steel

Material: Iron, Steel

Umeki Hon-tanebasami Seisakujyo

Mr. Shoji Umeki of Umeki Hon-tanebasami Seisakujyo, returned to his hometown of Tanegashima, after working for a metal company outside of Kagoshima Prefecture. He trained at Makise Tanebasami Seisakujyo, which has a history of more than 1,000 years in Tanegashima, and then became an apprentice to Yoshifumi Makise, a blacksmith for 37 generations, and inherited his skills as an apprentice. Mr. Umeki is the only one in Tanegashima who continues to make traditional scissors using the same traditional manufacturing methods as sword smiths, and all processes of scissor making are done by hand.

Mr. Shoji Umeki of Umeki Hon-tanebasami Seisakujyo, returned to his hometown of Tanegashima, after working for a metal company outside of Kagoshima Prefecture. He trained at Makise Tanebasami Seisakujyo, which has a history of more than 1,000 years in Tanegashima, and then became an apprentice to Yoshifumi Makise, a blacksmith for 37 generations, and inherited his skills as an apprentice. Mr. Umeki is the only one in Tanegashima who continues to make traditional scissors using the same traditional manufacturing methods as sword smiths, and all processes of scissor making are done by hand.

*Wipe dry and store after each use.

*If the shears are not to be used for an extended period of time, please apply a thin coat of oil to the entire surface and store.

*If the shears are not to be used for an extended period of time, please apply a thin coat of oil to the entire surface and store.

Beautiful handmade shears made by a traditional method in Kagoshima.

Tanegashima Island, located in the south of Kagoshima Prefecture, is rich in iron sand carried by the Kuroshio Current. It is said that Chinese blacksmiths introduced guns and shears in 1543. The traditional forging skills of Tanegashima have been passed down from guns and swords to shears and kitchen knives.

At its peak, there were nearly 30 manufacturing houses that distributed their products throughout Japan, but today there are only three. One of them, Umeki Hon-tanebasami Seisakujyo, is trying to preserve the technique and sharpness of Tanebasami shears for future generations.

The blade of Tanebasami shears is warped, or "neri," so that the blades rub against each other and are sharpened simultaneously with each cut. That's why you can enjoy these shears as everyday tools that will last you a long time.

Tanebasami shears, designated as a national intangible folk cultural property, have two blades that rub together to cut, which is considered a good omen and means "two people working together to open up their lives".

Tanegashima Island, located in the south of Kagoshima Prefecture, is rich in iron sand carried by the Kuroshio Current. It is said that Chinese blacksmiths introduced guns and shears in 1543. The traditional forging skills of Tanegashima have been passed down from guns and swords to shears and kitchen knives.

At its peak, there were nearly 30 manufacturing houses that distributed their products throughout Japan, but today there are only three. One of them, Umeki Hon-tanebasami Seisakujyo, is trying to preserve the technique and sharpness of Tanebasami shears for future generations.

The blade of Tanebasami shears is warped, or "neri," so that the blades rub against each other and are sharpened simultaneously with each cut. That's why you can enjoy these shears as everyday tools that will last you a long time.

Tanebasami shears, designated as a national intangible folk cultural property, have two blades that rub together to cut, which is considered a good omen and means "two people working together to open up their lives".

Dimensions: Length 180mm Width 60mm (Blade length 65mm)

Material: Iron, Steel

Material: Iron, Steel

Umeki Hon-tanebasami Seisakujyo

Mr. Shoji Umeki of Umeki Hon-tanebasami Seisakujyo, returned to his hometown of Tanegashima, after working for a metal company outside of Kagoshima Prefecture. He trained at Makise Tanebasami Seisakujyo, which has a history of more than 1,000 years in Tanegashima, and then became an apprentice to Yoshifumi Makise, a blacksmith for 37 generations, and inherited his skills as an apprentice. Mr. Umeki is the only one in Tanegashima who continues to make traditional scissors using the same traditional manufacturing methods as sword smiths, and all processes of scissor making are done by hand.

Mr. Shoji Umeki of Umeki Hon-tanebasami Seisakujyo, returned to his hometown of Tanegashima, after working for a metal company outside of Kagoshima Prefecture. He trained at Makise Tanebasami Seisakujyo, which has a history of more than 1,000 years in Tanegashima, and then became an apprentice to Yoshifumi Makise, a blacksmith for 37 generations, and inherited his skills as an apprentice. Mr. Umeki is the only one in Tanegashima who continues to make traditional scissors using the same traditional manufacturing methods as sword smiths, and all processes of scissor making are done by hand.

*Wipe dry and store after each use.

*If the shears are not to be used for an extended period of time, please apply a thin coat of oil to the entire surface and store.

*If the shears are not to be used for an extended period of time, please apply a thin coat of oil to the entire surface and store.