"Long-Life Design" does not merely refer to design or form. It also qualifies contexts such as the way in which goods are manufactured and sold.

Establishing an accessory brand that is handcrafted

throughout the entire manufacturing process.

HARIO was founded in 1921 as a manufacturer of laboratory glassware in Kanda, Tokyo. Other than beakers and flasks, they manufacture a wide array of products that take advantage of heat-resistant glass characteristics, such as coffee accessories and cooking ware. The establishment of this accessory brand known as HARIO Lampwork Factory has an inspiring history. It all started with the 2011 Great East Japan Earthquake. Due to the blackout of this earthquake, the electric furnace in HARIO's factory that was the size of a swimming pool stopped operating. This has caused the glass material that was always retained in liquid form inside the furnace to turn into an enormous clump. As it was impossible to remove the enormous glass clump, the furnace was eventually dismantled. The recovered glass was slowly broken up but HARIO could not think of how they could make use of it.

Nonetheless, HARIO had adopted a positive attitude toward the accident and embarked on a new challenge by saying, "Let's use these glass clumps to make accessories!" And thanks to the incident where the glass material hardened, the HARIO Lampwork Factory was established in 2013, producing an original accessory brand that is handcrafted throughout the entire manufacturing process with their motto, "Let's pass along the techniques of artisan handwork, which is the origin of corporations, to the succeeding generations!" The HARIO Lampwork Factory was highly regarded as an amazing business model that was born with the movement of establishing a handcraft accessory workshop and received the Good Design Award in 2014, which is considered one of Japan's most prestigious design awards.

The first shop comprised a gallery/shop with an adjoining glass workshop that opened in Nihonbashi, Tokyo. The interior and exterior use the same kind of bricks as the electric furnace that was once used in the HARIO factory. The people in the shop exterior photograph are Ms. Hirano (right), the shop manager and glass artisan, along with Ms. Suzuki (left), the shop staff. For our current coverage, after visiting the gallery/shop and conducting an interview regarding the HARIO Lampwork Factory, we took photographs of glass artisans showing the manufacturing process of accessories inside the workshop.

A wide array of designs associated with heat-resistant glass

Industrial glass is primarily "heat-resistant glass" and "soft glass." Heat-resistant glass can withstand heat and has a melting point of over 1000 degrees Celsius (1832 degrees Fahrenheit), requiring work with a burner. The word, "Lampwork" in the HARIO Lampwork Factory brand name refers to the handwork of crafting glass with a burner flame. Each HARIO Lampwork Factory accessory is handcrafted by an artisan and is characterized by a wide array of designs associated with heat-resistant glass. Also, even if heat-resistant glass breaks, its form can be recreated and repaired by reheating it with a burner.

Refined from natural minerals for a boundlessly pure material.

HARIO Lampwork Factory's accessories use materials that are refined from natural minerals. Also, the air bubble-removing agent used to keep the products air bubble-free contains salt and does not use any heavy metals. The heat-resistant borosilicate glass used by HARIO Lampwork Factory is lighter than other glass materials and is wearable. In addition, it is easy to work on and is considered an ideal material for glass artisans to make use of their fine skills. By adopting techniques that work with borosilicate glass through oxygen combustion, beautiful accessories can be created with artisan's handwork that cannot be reproduced through mass-production of machinery. Specifically speaking, it is characterized by work that is easy to expand and join glass components, making it possible to create designs that are delicate and have variety. Compared to ordinary glass accessories, you won't feel the strain from the weight, allowing it to be used as an everyday accessory. In our current coverage, we have particularly photographed the manufacturing process of the popular handmade "Earl Curve" and "Capsule" earrings among the HARIO Lampwork Factory accessories.

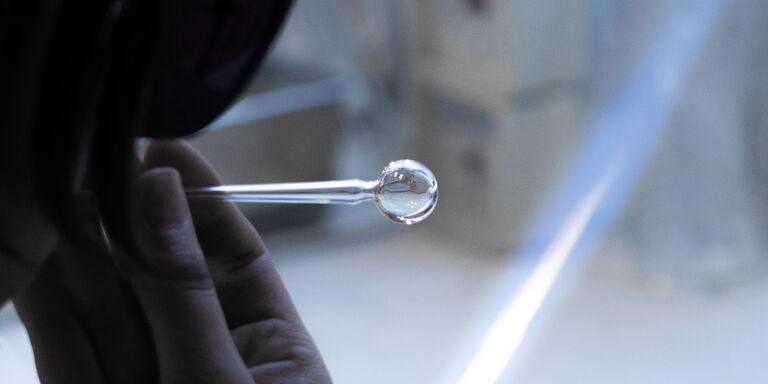

The manufacturing process of the "Earl Curve" handmade earrings

The "Earl Curve" handmade earrings that use a waterdrop as their motif are handcrafted by heating each glass rod piece with a burner. They are carefully crafted in a workshop based on diagrams created by an in-house designer. Although each piece of accessory may vary in size by several millimeters, this is due to the "warmth" that you can only experience from handcrafted products, which is one fascinating factor of HARIO Lampwork Factory.

The manufacturing process of the "Capsule" handmade earrings

The "Capsule" handmade earrings created as D&DEPARTMENT's original products are manufactured in a process where tubular glass rods are heated so that they expand. Then excessive glass is removed by stringing without deforming the spherical shape of the glass. The "Capsule" features a hollow design and utilizes a glass-blowing method where air is blown into the glass spheres during production.