Our original recycled cotton socks are slightly thicker, comfortable, durable and long lasting. We chose ribbed and jersey knit for a balanced length so they can be worn in all seasons and by all genders.

Original Socks Made from Recycle Cotton and Wool

Original Socks Made from Recycle Cotton and Wool

D&DEPARTMENT's original socks are made in Nara Prefecture, one of Japan's major sock manufacturing regions. They are made from recycled materials such as cotton from the yarn spinning process and leftover merino wool.

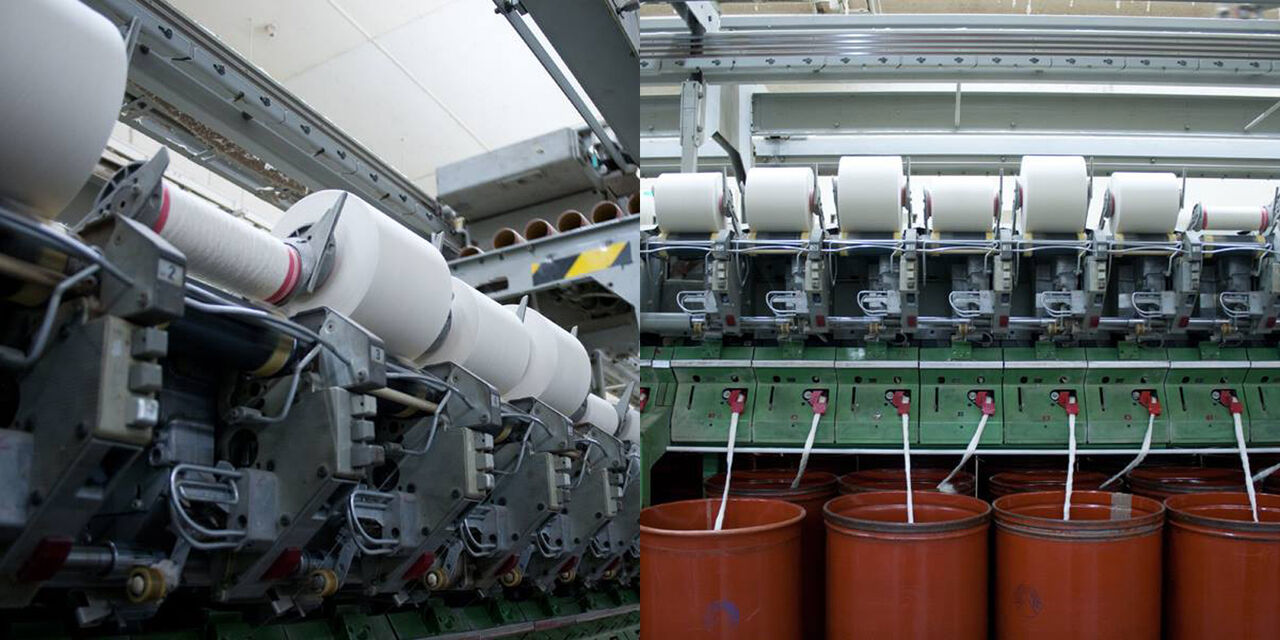

Thread from recycled cotton socks is spun by KAYAZAWA Shoten in Nara prefecture, whereas the sock manufacturing is done by Souki Inc., which is also located in Nara.

KAYAZAWA Shoten is a thread distributor founded in 1948 in Nara. We got to know them through the publication of "d design travel NARA". And then, in 2018, we decided to create original socks with them, because we empathized with their "efforts to promote sustainable manufacturing".

Seiichi Kayazawa, the president of KAYAZAWA Shoten, doesn't sell just any thread. He only sells thread that he is sure sock manufacturers would want. While growing up and watching his business, his son Ariatsu and his wife Ryoko founded "saredo", a sock brand that embodies the best of Nara's sock-manufacturing technology and skills.

"These may only be socks, yet have an importance nevertheless."

Recycled cotton socks of "saredo" use 100% waste cotton, a by-product of the yarn spinning process at domestic spinning mills, to apply their unique spinning process only to long fiber waste cotton. They have a slightly thick and comfortable feel. And, recycled wool socks are made from a blend of recycled merino wool waste from the cutting process and soft lamb wool for a soft textured finish. They are washed after completion to allow the yarn to absorb air and gain bulk for a fluffy and soft feel.

The Kayazawa couple's explanation of the "saredo" brand name is as follows.

"S"ustainable - We can go on forever, maintaining the present state without destroying the global environment.

"A"lternative - Another choice, heterogeneous, not in type.

"RE"novation - Innovation, repair. We create new value, reproduce and reconstruct.

"DO"mestic - Based on the domestic inspiration of the country = the do-it-yourself spirit.

Mr. and Mrs. Kayazawa work on manufacturing with 4 keywords "Faith", "Honesty", "Humility" and "Delicate", based on the spirituality and artisan disposition of the Japanese people. Moreover, they propose and market thread that gives the "nevertheless" impression, rather than "only be..." one.

We recycle materials that would normally be discarded without creating waste, rather than simply creating a product cycle. We also like to meet people from every corner of Japan and emphasize activities to expand the sphere of production. Using the 4 words as keywords, we propose "a sustainable lifestyle spun from waste cotton". We feel that everything about Nara's craftsmanship is embodied in these words: "These may only be socks, yet have an importance nevertheless."